|

|

Telemanipulation for Micromanipulation and MicrosurgeryOn this page... (hide) Retinal MicrosurgerySelected PublicationsM. Nambi, P. S. Bernstein, and J. J. Abbott, "A Compact Retinal-surgery Telemanipulator that uses Disposable Instruments," Int. Conf. Medical Image Computing and Computer-Assisted Intervention, 2015. CollaboratorsIntuitive Tele-operation of Micromanipulators with Piezoelectric Stick-slip Actuators

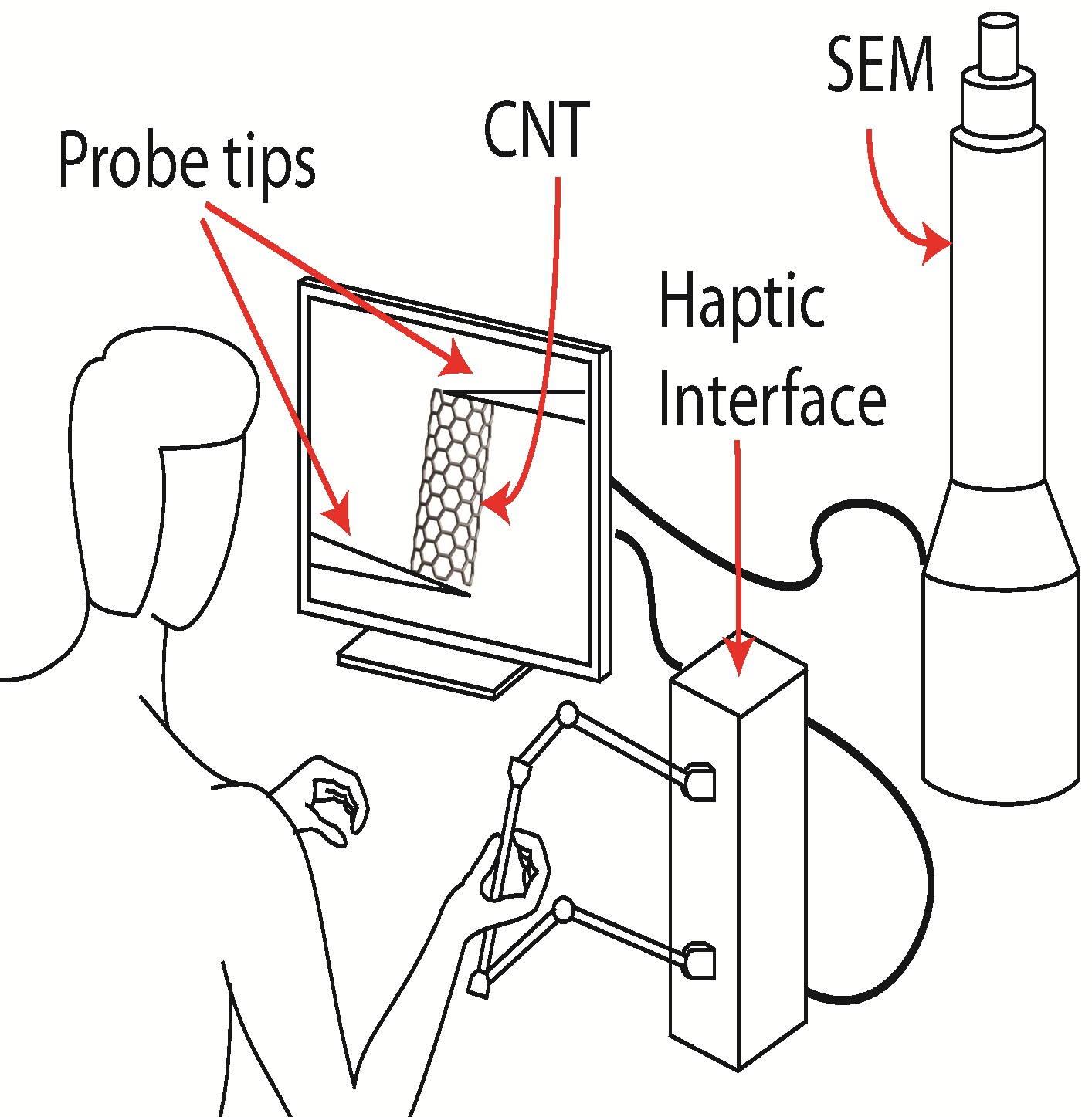

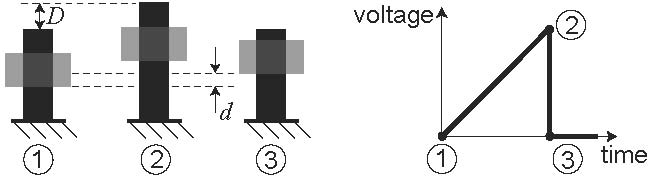

Micro/Nano-manipulation deals with handling of extremely small objects on the order of 10-3 to 10-9m. Development of scanning and transmission electron microscopes (SEMs/TEMs) has enabled researchers to image and manipulate objects as small as 1\,nm in size. However, due to difficulties in simultaneous imaging and manipulating, micro/nano-manipulation is still a laborious task requiring great patience. The goal of our research is to enable tele-operated rate control of micro/nano-manipulators without relying on any feedback from the vision system, other than the human user looking at the microscope image. This involves obtaining empirical models for the micro/nano-manipulator joints so that reliable position estimates can be obtained in the absence of feedback and development of control methods to move the end-effector using position estimates obtained from the open-loop models. Through intelligent algorithm development and drift compensation techniques we can greatly improve the efficiency with which such piezoelectric stick-slip actuators are operated.  Functional description of a piezoelectric stick-slip actuator. Piezoelectric stick-slip actuators have become the foundation of modern micro/nano-manipulation due to their simple structure, high positional accuracy, unlimited movable distance, and high stability as they are supported by guiding surfaces. These actuators consist of a piezoelectric element and a sliding mass that moves relative to the piezoelectric element. A saw-tooth voltage is applied to the piezoelectric element. As the voltage slowly increases from 1 to 2, the piezoelectric element stretches by a distance D, and due to stick-slip friction between the piezoelectric element and the sliding mass, the sliding mass also advances (stick phase). When the voltage is quickly reduced from 2 to 3, the piezoelectric element quickly shrinks, but the inertia of the sliding mass prohibits it from moving backward as quickly, resulting in a net forward displacement of the sliding mass of d < D (slip phase). Typically, these actuators have no sensor feedback, and hence, the individual joints of the manipulators are controlled open-loop, using one knob per joint. It is not always clear what combination of joint commands will lead to a desired end-effector movement from only a microscope image. In addition, manipulators are often mounted on moving stages and on different surfaces at varying angles. The user observing the end-effector of such a manipulator under a microscope has to perform the difficult task of mapping the image frame to his/her egocentric frame of reference. Use of multiple manipulators further complicates the situation. Thus, micro/nano-manipulation is currently unintuitive and time consuming.

Selected PublicationsA. Damani, M. Nambi, and J. J. Abbott, "An Empirical Study of Static Loading on Piezoelectric Stick-Slip Actuators of Micromanipulators," Int. Symp. Experimental Robotics, 2012.

M. Nambi, A. Damani, and J. J. Abbott, "Toward Intuitive Teleoperation of Micro/Nano-Manipulators with Piezoelectric Stick-Slip Actuators," IEEE/RSJ Int. Conf. Intelligent Robots and Systems, pp. 445-450, 2011.

|